Competitive Advantage The Power of Supply Chain Software in a Digital World

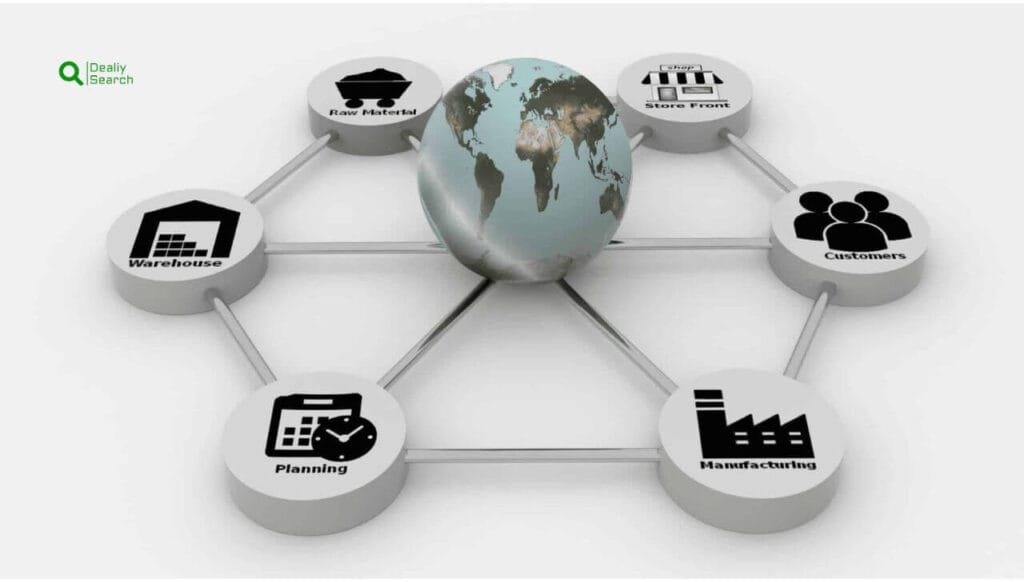

Efficient supply chain management is crucial for businesses to stay competitive in today’s global economy. Supply chain software streamlines the flow of goods, information, and services, managing everything from inventory control to logistics and supplier collaboration. By automating key processes, it reduces costs, enhances visibility, and improves decision-making with real-time data and analytics. With the rise of e-commerce and globalization, traditional methods no longer suffice.

Supply chain software solutions, like warehouse management systems (WMS) and ERP integrations, offer a comprehensive approach to manage all aspects of the supply chain. Whether for small businesses or large enterprises, the right software can improve operational efficiency, customer satisfaction, and profitability. This blog post delves into the most transformative innovations, highlighting how they effectively empower businesses to navigate modern chain complexities.

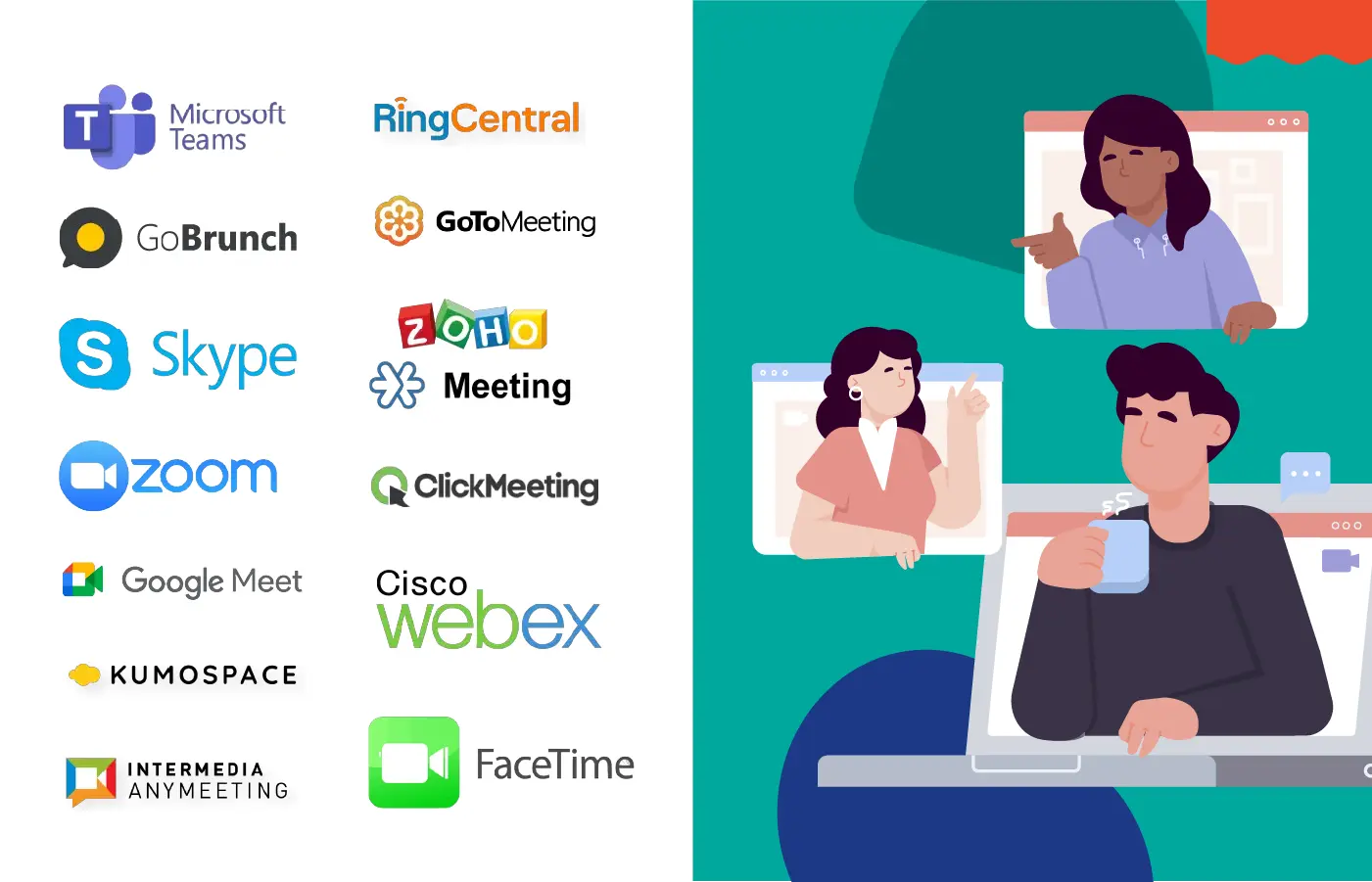

What Is Supply Chain Software?

Supply chain software is a tool designed to manage and optimize the flow of goods, services, and information throughout a business’s supply chain. It automates key processes like inventory control, demand forecasting, procurement, logistics, and order fulfillment, improving efficiency and reducing costs. By providing real-time data and advanced analytics, it enhances decision-making and visibility. Supply chain software solutions, such as warehouse management systems (WMS) and ERP integrations, help businesses streamline operations, boost profitability, and ensure customer satisfaction.

What are the typical features of supply chain software?

Inventory Management: Tracks stock levels, optimizes reorder points, and ensures inventory accuracy.

Order Management: Automates order processing, tracking, and fulfillment to improve efficiency and customer satisfaction.

Demand Forecasting: Uses historical data and analytics to predict future demand, helping with better inventory planning.

Procurement Management: Streamlines purchasing, supplier management, and procurement workflows.

Warehouse Management: Manages warehouse operations, including storage, picking, packing, and shipping.

Logistics and Transportation Management: Optimizes shipping routes, carrier selection, and delivery schedules.

Supplier Collaboration: Facilitates real-time communication and coordination with suppliers.

Analytics and Reporting: Provides real-time insights and data analysis to support decision-making and performance tracking.

Integration with ERP/CRM: Allows seamless integration with other business systems like ERP and CRM for smoother operations.

Mobile Access: Enables on-the-go access to supply chain data for better decision-making and management.

important factors to consider when purchasing supply chain software

When purchasing supply chain software, it’s essential to consider several key factors to ensure it meets the needs of your business. First, evaluate the software’s scalability, as your company’s needs may grow over time, and the system should be able to accommodate that growth. Integration capabilities are also crucial; the software should easily integrate with existing systems, such as your ERP or CRM software, to ensure seamless data flow across the organization. Usability is another important factor opt for software with an intuitive interface that is easy for your team to adopt, minimizing training time. Additionally, consider the software’s flexibility in handling various types of supply chain operations, including procurement, inventory management, and logistics. The software’s ability to offer real-time data and analytics can also improve decision-making and supply chain visibility. Finally, consider the vendor’s customer support and reputation in the market, as timely support and ongoing updates can be critical to maintaining the efficiency and security of your system.

Benefits of Supply Chain Software

Improved Efficiency: Automates and streamlines processes, reducing manual tasks and minimizing human error, leading to faster and more accurate operations.

Cost Reduction: Optimizes inventory levels, improves demand forecasting, and enhances logistics, helping reduce excess stock, shipping costs, and operational expenses.

Real-Time Data and Visibility: Provides real-time insights into inventory, shipments, and supplier performance, enabling better decision-making and proactive problem-solving.

Better Demand Forecasting: Uses historical data and analytics to predict demand, helping businesses plan inventory and procurement more accurately, avoiding stock outs or overstocking.

Enhanced Collaboration: Facilitates seamless communication between suppliers, distributors, and other stakeholders, improving coordination and reducing delays.

Improved Customer Satisfaction: By ensuring timely deliveries and accurate order fulfillment, businesses can provide better service to customers, improving loyalty and satisfaction.

Scalability: As businesses grow, supply chain software can scale to handle increasing complexity, larger volumes, and more sophisticated supply chain needs.

Data-Driven Decision Making: Advanced analytics and reporting tools allow businesses to make informed decisions based on data, improving performance across the supply chain.

Risk Mitigation: Identifies potential disruptions, such as supply shortages or transportation delays, allowing businesses to take preventive actions.

Regulatory Compliance: Helps businesses stay compliant with industry standards and regulations, reducing the risk of penalties or legal issues.

What Are The Trends In Supply Chain Software?

Supply chain software is evolving rapidly to meet the demands of today’s dynamic business environment. Some of the key trends include:

- AI and Machine Learning Integration: AI and machine learning are being used to enhance demand forecasting, optimize inventory management, and predict potential disruptions. These technologies can analyze vast amounts of data to make real-time decisions, improving efficiency and accuracy.

- Cloud-Based Solutions: More companies are adopting cloud-based supply chain software because of its flexibility, scalability, and cost-efficiency. Cloud solutions enable businesses to access their supply chain systems from anywhere and facilitate easier collaboration across global teams.

- Blockchain for Transparency and Security: Blockchain technology is gaining traction in supply chains for its ability to provide transparency and enhance security. It allows for secure, immutable tracking of goods and transactions, reducing fraud and improving trust among supply chain partners.

- IoT Integration: The Internet of Things (IoT) is becoming increasingly prevalent in supply chains, with sensors and devices tracking goods in real-time. This integration helps companies monitor product conditions (e.g., temperature-sensitive items) and improve the overall visibility of goods in transit.

- Automation and Robotics: Automation is transforming warehousing and logistics operations. Robotics and automated systems are streamlining picking, packing, and sorting processes, reducing labor costs and improving accuracy and speed.

- Sustainability and Green Logistics: As sustainability becomes a priority for businesses and consumers, supply chain software is incorporating tools to track carbon emissions, optimize transportation routes for fuel efficiency, and manage waste, ensuring companies meet environmental goals.

- Collaboration and Data Sharing: Modern supply chain software is focusing on better collaboration tools. By allowing all partners in the supply chain to share data and insights in real time, businesses can respond faster to changes and improve overall performance.

Embracing the Digital Shift Key Supply Chain Software Innovations

Embracing digital shifts in supply chain management, key software innovations like AI, IoT, and blockchain enhance efficiency, resilience, and customer satisfaction, helping businesses stay competitive and adaptable in a fast-paced market.

AI-Driven Predictive Analytics

Supply chain software now leverages AI and ML for predictive analytics, offering wonderful insights into demand forecasting and inventory optimization. Companies like Walmart and Procter & Gamble have successfully integrated these technologies to enhance inventory management and customer satisfaction.

Blockchain technology revolutionizes supply chain transparency by creating unalterable records of every transaction. This innovation boosts security and trust and streamlines operations, as seen with IBM’s Food Trust platform.

Real-Time Tracking and Monitoring

IoT devices integrated into supply chain software provide real-time data on product location, condition, and environmental factors, dramatically improving logistics and reducing waste. Companies like DHL utilize IoT to ensure sensitive goods’ safe and timely delivery.

Robotics technology, including collaborative robots (cobots), automates repetitive tasks in warehouses, enhancing productivity and safety. Amazon’s use of robotics in warehouse operations exemplifies this trend, significantly reducing delivery times.

Customization and Flexibility in Production

3D printing technology integrated into supply chain software supports on-demand production, minimizing the need for extensive inventories and enabling customization at scale, as demonstrated by Adidas’s approach to manufacturing footwear.

Supply chain software innovations now incorporate AR and VR to enhance employee training and operational procedures. DHL’s use of AR for warehouse operations illustrates how these technologies improve accuracy and productivity.

Utilizing vast data sets, supply chain software can now more accurately predict trends and consumer behavior, allowing for more effective inventory management and operational decisions.

Software platforms enable real-time collaboration and communication across the supply chain, improving responsiveness and efficiency. Wal-Mart’s collaborative efforts with suppliers highlight the benefits of this innovation.

Autonomous transport technologies like drones and self-driving vehicles are becoming integral to supply chain software, enhancing delivery speeds and reducing operational costs. Amazon’s drone delivery initiative is a prime example.

Frequently Asked Question

Read the questions to learn more about supply chain software.

What is supply chain software?

Supply chain software is a digital solution that helps businesses manage and optimize the flow of goods, services, and information throughout their supply chain, including inventory management, procurement, logistics, and order fulfillment.

How can supply chain software benefit my business?

It improves efficiency by automating processes, reduces costs through better inventory and logistics management, enhances real-time data visibility, and improves decision-making, leading to increased profitability and customer satisfaction.

Is supply chain software easy to implement?

The ease of implementation depends on the complexity of the software and the business’s current infrastructure. However, most modern solutions offer user-friendly interfaces and integration capabilities that make implementation smoother, often with vendor support and training.

Can supply chain software integrate with other business systems?

Yes, most supply chain software can integrate with existing systems like Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), and Warehouse Management Systems (WMS) to ensure smooth data flow across the business.

What features should I look for in supply chain software?

Key features to consider include inventory management, order processing, demand forecasting, logistics optimization, real-time data analytics, supplier collaboration, and integration capabilities with other business systems.

How does supply chain software help with risk management?

It helps identify potential disruptions by analyzing data, forecasting demand, and offering real-time visibility into the supply chain. This allows businesses to take proactive measures to mitigate risks like supply shortages or delays.

Is supply chain software suitable for small businesses?

Yes, there are scalable and cost-effective supply chain software solutions designed specifically for small businesses. These solutions help smaller companies streamline operations, improve efficiency, and scale up as they grow.

Conclusion

The supply chain management landscape is evolving due to technological advancements and a growing need for efficiency and customer satisfaction. Innovations in supply chain software are central to this shift, offering businesses tools to remain competitive. Future integration of AI, IoT, blockchain, and other technologies will enhance operational capabilities, leading to more resilient and sustainable supply chains. Embracing these innovations is essential for businesses aiming to thrive. In conclusion, supply chain software streamlines operations, boosts efficiency, and improves competitiveness by automating processes like inventory management and logistics. Advanced features such as real-time analytics and AI are transforming supply chains, ensuring better visibility, adaptability, and scalability for businesses of all sizes.